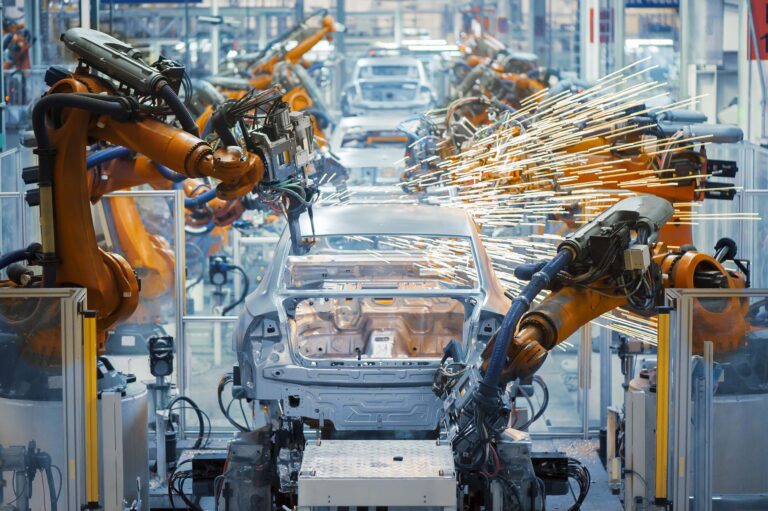

Industrial

Challenging industrial environments require only the best

Heat. Cold. Humidity. Vibrations. Shocks.

Life in industrial environments is tough. Machines vibrate, spin things around and slam things in their place. Temperatures go low and rise high. Flawless industrial precision, high speed and constant production are the expectation.

Is your equipment up for the task?

Tough environments. Tougher requirements.

Industrial environments exert extreme environmental stress on equipment and their components while requiring meticulous precision and top-level performance.

At the scale that modern factories operate at, every percent matters. A single percent of extra performance can translate into millions of dollars of additional profits from higher efficiencies and higher yield. Now imagine the implications of a massive jump in performance.

However, every industrial application is different, requiring customized solutions that take every variable into account to generate performance and efficiency gains. One size fits all could not be further from the truth in industrial applications – putting an extra emphasis on customization.

But performance is not all that matters. Especially not in industrial applications. If a five-percent boost in performance comes at a cost of even one percent in decreased reliability, the benefits of the increase in performance is only a malfunction away from being completely wiped out – or worse.

Similarly, an increase in device reliability can have a substantial impact on production uptime. A device malfunction that causes all production to stop translates into a massive decrease in output and therefore revenue. Troubleshooting equipment can also come at considerable costs.

The right balance between performance and reliability, in other words, can mean the difference between a huge boost in profits and a painful decrease in revenues. That is why finding the right partner matters.

Key challenges

Precision and performance above all

Advanced manufacturing processes rely on extreme precision and incredible performance to produce high-quality products at a staggering pace.

Extremely costly downtime

Downtime comes at a huge cost in industrial applications, emphasizing the critical importance of device stability and reliability.

Uniquely demanding

Since industrial applications vary greatly in terms of environmental challenges and requirements, every solution must be customized and tuned for its specific application.

Our solutions

Unbeatable performance

Our flash storage devices are designed to deliver the cutting-edge sustained performance that industrial applications require.

Unwavering stability

Our solutions put stability and reliability first – making sure that performance is stable and that modules remain operational no matter what challenges come their way.

Truly customized solutions

Exascend’s customization services are second to none with advanced in-house hardware and firmware tailoring – guaranteeing that each product is perfectly optimized for its intended application.

Recommended technologies

Adaptive Thermal Control

Our unique Adaptive Thermal Control™ technology tackles the issue of overheating and thermal throttling that is unavoidable in high-performance PCIe NVMe flash storage devices.

Unlimited Over-Provisioning

Exascend offers unlimited over-provisioning (OP), allowing customers to set the ideal level of OP to match their application’s exact demands. No artificial limitations. Unlimited flexibility.

Power Tuning

Our unique level of control over hardware, firmware and manufacturing enables us to provide unmatched tuning services. By tuning the performance of our product specifically for your applications, we can achieve the highest possible performance to thermals and performance to power ratios.

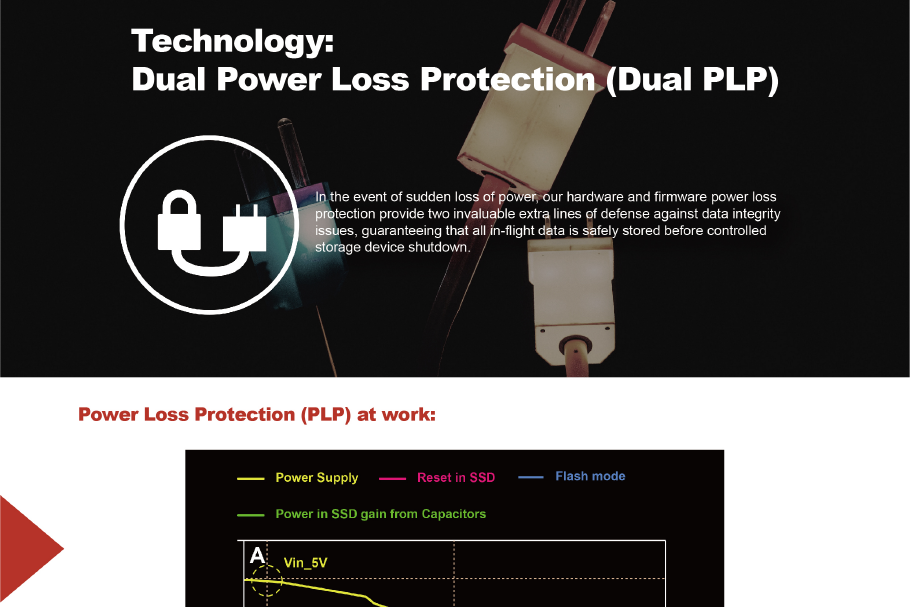

Dual Power Loss Protection

In the event of sudden loss of power, our hardware and firmware power loss protection provide two invaluable extra lines of defense against data integrity issues, guaranteeing that all in-flight data is safely stored before controlled storage device shutdown.

Wide Temperature

Exascend’s wide temperature technology leverages a unique combination of high-quality components, purpose-designed hardware and highly-optimized firmware to deliver unmatched wide temperature performance and stability.

Recommended products

- PCIe 4.0 (NVMe 1.4) interface

- 3D TLC NAND flash

- Up to 8 TB capacity

- 3,500 MB/s sustained read

- 3,000 MB/s sustained write

- PCIe 3.0 (NVMe 1.2) interface

- 3D TLC NAND flash

- Up to 8 TB capacity

- 3,100 MB/s sustained read

- 1,600 MB/s sustained write

- SATA-III interface

- 3D TLC NAND flash

- Up to 4 TB capacity

- 550 MB/s sustained read

- 535 MB/s sustained write