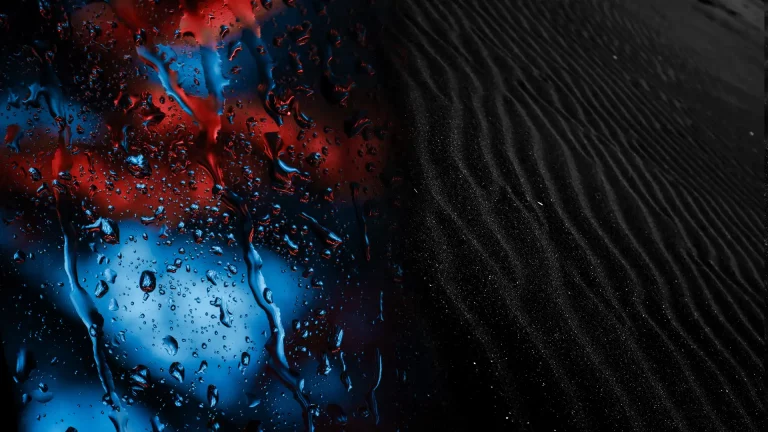

Conformal Coating

Shielding the Entire SSD against Moisture and Contaminants

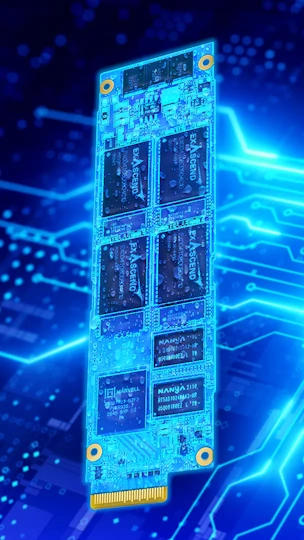

Exascend employs the formidable technology of conformal coating to bolster the resilience of its SSDs against environmental threats. This advanced technique entails applying a water and particle-resistant coating to both the printed circuit board (PCB) and integrated components. As a result, the likelihood of contaminants and moisture impacting the SSD’s performance is significantly reduced.

Conformal coating is particularly favored by Exascend’s clients in sectors like mission-critical operations, industrial automation, edge computing, and transportation. These industries frequently contend with contaminants, and the ramifications of SSD malfunctions can be severe. Hence, conformal coating is embraced as an invaluable supplementary protective measure.

Meeting Stringent Compliance Standards

In our conformal coating approach, we rely on HumiSeal® 1A33, a urethane-based compound engineered for chemical resistance and qualified under MIL-I-46058C standards. This material, designed specifically for PCBs, boasts an impeccable track record when applied to SSDs.

Exascend’s coating products adhere to stringent parameters, including controlled thickness ranging from 30um to 130um, compliance with IPC-HDBK-830 and IPC-CC-830 standards, and adherence to RoHS, REACH, and UL94 V-0 standards. The coating glue’s applicability spans an ambient temperature range of -65°C to 125°C, ensuring versatility in diverse environmental conditions.

Precision Coating Process for Enhanced SSD Protection

Exascend employs an automated process to ensure the uniform application of conformal coatings across the entire SSD, excluding the connectors. This automated method guarantees an even layer with the desired thickness of the protective compound.

Following the coating application, specialized equipment is utilized to cure the conformal coating compound. This process enhances its durability and effectiveness. Quality and thickness of the coating are rigorously validated using UV light and a thickness gauge.

The final product displays a noticeable shine due to the coating’s reflective qualities. Beyond aesthetics, this finish signifies robust protection. With the coating applied and quality assured, the SSD is fully prepared for seamless integration into even the most demanding customer applications.

Recommended products

- PCIe Gen4 x4 / NVMe 1.4

- Up to 15.36TB capacity

- Up to 3,500 MB/s sustained performance

- Op. Temp -40°C to 85°C

- Conformal Coating and Underfill featured

- SATA 6.0Gb/s

- Up to 7.68TB capacity

- Up to 550 MB/s sustained performance

- Op. Temp -40°C to 85°C

- Conformal Coating and Underfill featured

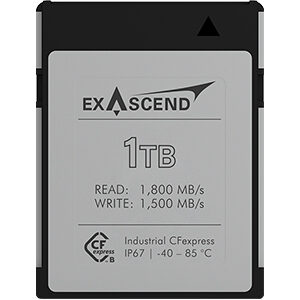

- PCIe Gen3 x2

- Up to 1TB capacity

- Up to 1,800 MB/s sustained performance

- Op. Temp -40°C to 85°C

- For professional photographers

- VPG400-certified

- Up to 1TB capacity

- Up to 1,850 MB/s sustained performance