When it comes to selecting the right capacitors for your electronic devices, two popular options to consider are tantalum and aluminum electrolytic capacitors. Each type has its unique advantages, and understanding their characteristics can help you make an informed decision for your specific needs.

First, let’s briefly define what an electrolytic capacitor is. An electrolytic capacitor is a polarized capacitor that utilizes an oxide layer on an anode or positive metal plate to provide capacitance. These capacitors are commonly used in flash memory manufacturing to store and release electric charges, providing emergency power supplies in case of sudden power failures.

One important aspect of electrolytic capacitors is the dielectric material they use, which can be solid or non-solid. High-end motherboards often prefer solid capacitors made from aluminum, tantalum, or polymer. Solid capacitors eliminate the risk of leakage or explosions caused by electrolytes expanding due to overheating.

At Exascend, we utilize both aluminum and tantalum electrolytic capacitors, taking advantage of their unique benefits. Let’s explore the advantages of each type.

Advantages of Tantalum Electrolytic Capacitors

- Smaller Size for High Capacitance: Tantalum capacitors have thin dielectric layers, allowing them to offer higher capacitance values per unit volume. This compactness makes them ideal for weight-sensitive applications.

- Withstands Higher Temperatures: Tantalum capacitors have a wide operating temperature range of -55°C–125°C, making them suitable for various industrial, enterprise, automotive, commercial, and consumer electronics applications. They excel in rugged environments and are commonly used in industrial-grade SSDs.

- Excellent Reliability: Tantalum capacitors exhibit a rise in capacitance with temperature and an increase in capacitance as the power supply load becomes heavier. This property makes them well-suited for energy storage and switched-mode power supplies with variable loads, providing long service life and high reliability.

Advantages of Aluminum Electrolytic Capacitors

- Large Capacitance at a Competitive Price: Although aluminum capacitors don’t match tantalum capacitors in terms of capacitance-to-size ratio, they offer a significant amount of capacitance at an attractive price point. They are compact and cost-effective.

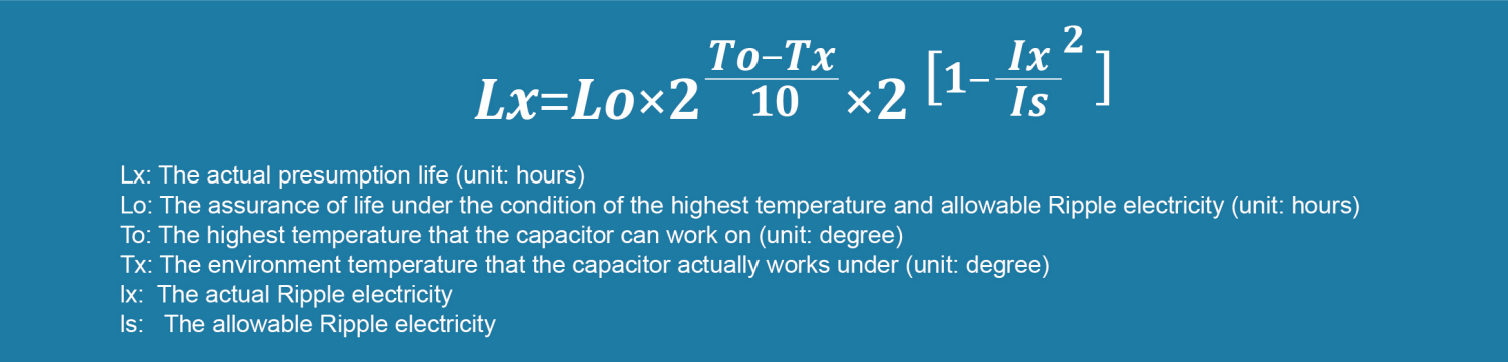

- Great Reliability Under Normal Use: The lifespan of aluminum electrolytic capacitors depends on environmental and electrical factors. Temperature, humidity, atmospheric pressure, vibration, operating voltage, ripple current, and charge-discharge duty cycle all influence their life. Temperature, particularly the ambient temperature and internal heating due to ripple current, is the most critical factor.

Exascend employs a formula to estimate capacitor life, considering these factors.

At Exascend, we use aluminum electrolytic capacitors that are specified at 5000h@105°C. Since the capacitor is fully charged upon SSD power-on and doesn’t go through continuous charge and discharge cycles, the actual ripple current is minimal after the capacitor charges completely. This results in a small value for lx/ls in the formula mentioned above. With this design, we expect the actual life of the capacitor to be approximately 40,000 hours (4.6 years) when the drive operates under 85°C and 2,560,000 hours when it operates under 25°C.

Exascend’s Use of Tantalum and Aluminum Capacitors

Exascend offers SSDs with Wide Temperature (-40°C–85°C) and Extended Temperature (-20°C–85°C) operating ranges. For these SSDs, tantalum capacitors can be customized to provide an extra line of defense against unexpected power losses.

For SSDs operating between 0°C–70°C, we recommend using aluminum capacitors due to their cost-effectiveness and reliability, especially in applications without frequent charge and discharge cycles. Many of Exascend’s enterprise-class 2.5-inch SATA, U.2 and E1.S SSDs come equipped with aluminum capacitors by default. We also offer customization options upon request.

If you have any inquiries or need further assistance in choosing the right capacitors for your specific requirements, please feel free to contact us. We’ll be happy to help.